Focusing on customers, concentrating on products, becoming a value bridge trusted by partners!

In 2025, the global automotive industry is accelerating towards the deep waters of intelligence and electrification, and China, as the worlds largest market for new energy vehicles, is leading the core direction of this transformation. Against this backdrop, Silergy will hold its first Developer Conference at Silergy Tower in Hangzhou on April 11, 2025, focusing on the opportunities of domestic substitution of automotive core chips and sharing Silergys innovative solutions and ecological layout in key areas such as BMS AFE, MCU, and SerDes. 01. Domestic substitution of automotive chips Domestic substitution of automotive chips: A Leap from usable to reliable : The domestic production rate of automotive chips in China is less than 20%, and key areas are still highly dependent on imports. Relying on its fully self-developed technology chain and localized service capabilities, Silergy has launched a matrix of automotive-grade chip alternative solutions, covering core scenarios such as power systems, intelligent cockpits, and body control. Sili Jie was the first to complete: - ASIL-D-level functional safety certification, meeting the highest standard of ISO 26262; A fully localized testing and certification system throughout the entire process significantly shortens the vehicle entry cycle. The independent and controllable IP core design breaks through the risk of being strangled in the international supply chain. 02. Upgrade of intelligent control driven by the autonomous kernel The Silergy SA32D series MCU is based on the high-performance and highly reliable RISC-V core, featuring ultra-high computing performance and rich peripherals. It is mainly used in high-security edge computing and control scenarios such as BMU in power battery management systems, main drive motor control (Traction Inverter), chassis applications (ONE-BOX/ESC), area control (ZCU), and some ADAS applications. This series of products complies with the EC-Q100 standard and the functional safety ISO

Saarbruken, Germany, December 5, 2024 - HighTec EDV Systeme GmbH, the worlds leading provider of automotive C/C++ compiler solutions, has announced full support for the RISC-V IP from Chipset. The HighTec compiler is an open source automotive C/C++ compiler tool based on LLVM and is ISO 26262 ASIL D certified for safety. Automotive software developers working on RISC-V architectures benefit from these tools to seamlessly support the core to functionally safety-certified RISC-V cores, generating compact and highly reliable code for the most demanding automotive applications with high performance and high safety requirements. Xinlai has received two Exida ASIL-D product certifications for NA300 and NA900 in the past two years, which confirms the high safety and reliability of Xinlai Automotive grade products and recognizes Xinlais strong capabilities in developing IP. This is significant not only for the company, but also for the entire RISC-V ecosystem in automotive electronics: With this certification, the company becomes the first RISC-V IP supplier in the world to receive ASIL-D product certification. Xinlai aims to increase the confidence of domestic and foreign customers in using RISC-V to manufacture automotive chips. The HighTec C/C++ automotive compiler meets all technical requirements to take full advantage of the powerful performance and unique safety features of the RISC-V core. The compiler is based on LLVM (Low Level Virtual Machine) open source technology and is known for its short build time and advanced code optimization features. HighTecs functional safety certified C/C++ compiler also speeds the development and certification of functional safety automotive applications with an accreditation kit. In close cooperation with Core technology, the SA32D610/408 series of NA900 IP based on core high-performance RISC-V architecture will be officially released as the main core, with the important peripheral IP developed by Sillij, as well as the fast connecti

1. AI server AI development has been integrated into multiple industries and fields and has become the focus of global attention. silergy has launched a series of solutions including digital power controller, digital to analog converter, power monitor, current detection op amp, temperature sensor, timing controller, clock buffer, ESD, etc., to inject core power into AI computing power in many aspects. SQ51225 Gauge level two-channel polyphase power controller ◆ Multi-phase dual-channel output controller supports flexible dual-channel phase number customization and pulse timing distribution, N+M 5 ◆ The output voltage adopts remote differential sampling feedback ◆ Output voltage adjustment range and mode: - 0.25 to 1.52V, 5mV step table -0.25 ~ 1.52V, linear mode (1mV user-defined form) ◆ Programmable soft start slope and output voltage build slope ◆ Programmable pin flexible definition, including: - Eight PMBus device addresses - Dual 16 built-in output voltage configuration ◆ Comply with PMBus 1.3.1 protocol, compatible with 1.8/3.3V logic level; AVSBus interface speeds up to 30MHz ◆ Dynamically adjust the output voltage according to the load demand and respond in time ◆ System operation control, real-time status monitoring and fault detection report ◆ Flexible PWM design ensures compatibility with different types of intelligent power levels ◆ Automatic loop compensation function ◆ Automatic phase current balance function ◆ Comprehensive protection strategy and adjustable threshold ◆ Built-in NVM to store customized configurations ◆ 300kHz to 2MHz switching frequency setting ◆ Package form: QFN77-48 SQ29663 16V/70A integrated power level DrMOS ◆ 70A output current capability ◆ Integrated driver and power MOSFET tube ◆ VDRV/VCC/VBST/VIN UVLO ◆ Support maximum switching frequency: 1.0MHz ◆ Support 3.3V / 5V PWM input, compatible with 3-state logic ◆ Integrated 5mV /A current detection and reporting ◆ Integrated 8mV /℃ tem

One wave followed another. Intel, struggling in the competitive chip market, cut 15,000 jobs and suspended its dividend, sending its shares down more than 20% on the day, the biggest drop since 1982. On the other hand, the global automotive semiconductor giant Infineon has announced that the company will lay off 1,400 people worldwide and move another 1,400 jobs to countries and regions with lower labor costs. The moves of industry giants are a sample that reflects the overall trend of the semiconductor industry. Even so, domestic chip startups naturally can not escape the pain - blocked financing, IPO failure, bankruptcy liquidation, mergers and acquisitions difficult... The global semiconductor landscape is changing. In the dilemma of running out of ammunition and the strange move of surviving, how to break the situation of domestic chip enterprises in the mire has become a key proposition. Domestic chip startups are Mired in the mire. In recent years, the global semiconductor market has experienced several twists and turns. A few years ago, the capital sought after, everywhere gold track, suddenly ushered in the capital winter. Under the cold winter, can not see clearly, dare not invest, no money once became the keynote throughout the industry, and the era of semiconductor blind investment can also make money came to an end. This will be a bad luck for domestic chip startups, especially those that continue to rely on financing for blood transfusion and lack of self-hematopoietic ability. 01, the enterprise closed down The collapse is perhaps the most direct evidence of the shift in capital. As we all know, semiconductor is an industry with huge initial investment and long return of funds, and capital is extremely important to its development. For companies with insufficient self-hematopoietic ability, the result of long-term outliving is a substantial decline in performance and profit loss. In the past, when capital markets were hot, none of this was a problem. B

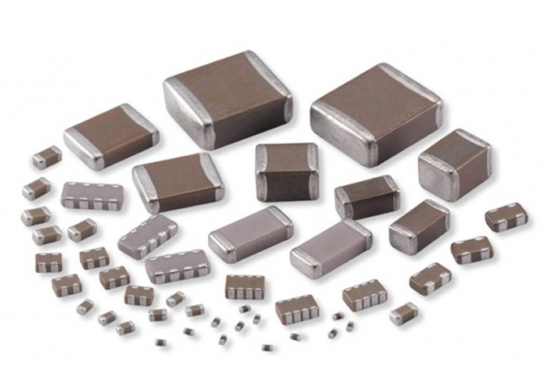

This article is from: Financial AI Telegram The global passive component industry has a new round of price increases, and its price increases are far higher than the previous rounds, with the highest increase forecast to reach 20%. The main drivers of this increase are the upcoming smartphone season, the recovery of the PC market and the surge of more than 30% in silver prices this year. Murata, TDK and Sun inductor manufacturers, Guoju and Huaxin Technology Group, all plan to raise the price of multi-layer inductors and magnetic beads, and the report is expected that large-size products will be the first to increase prices, by between 10% and 20%. Notice: The copyright of this article belongs to the original author, the article is only for sharing use, does not represent the position of the company, such as copyright issues, please contact us to delete.